In August 2019, the Chiron Super Sport 300+1 became the first production car ever to break the 300-mph barrier. At a speed of 304.773 mph (490.484 km/h), it is since considered the fastest series production car in the world. With the Chiron Super Sport2, Bugatti offers extreme longitudinal dynamics and the maximum bandwidth within the “Bugatti Spectrum of Performance”.

Achieving a top speed of 440 km/h is not simply a matter of increasing power output. It requires many modifications of the car’s body, engine and chassis, in order to make traveling at such extreme speeds safe, comfortable and reliable – the forte of the French luxury carmaker. With attention to detail and the pursuit of technical perfection, Bugatti’s engineers developed a trailblazing hyper sports car.

Optimized Aerodynamics

A top speed beyond 400 km/h not only requires a powerful engine, but also a very low air resistance. Bugatti engineers and designers worked for months to find the optimum aero-balance for the Chiron Super Sport, achieving the lowest drag coefficient and the maximum downforce.

New Air Curtains

Above 400 km/h, a balanced and safe driving behavior is paramount. “Only perfect incoming airflow at the front of the car will keep harmful turbulence at bay and ensure that the airflow around the car stays clean,” says Frank Heyl, Deputy Design Director at Bugatti.

In order to minimize turbulence on the sides, the team integrated newly developed air curtains in front, similar to wings, which help guide the air around corners in an optimal way. At the same time, the air curtains also make sure that the airflow follows the body’s contours as closely as possible to stabilize the car. This lowers pressure losses and resistance – the ideal skin for fast driving “shaped by speed”. To achieve a perfect airflow, Bugatti engineers ran numerous simulations to arrive at the ideal curvature and thickness of the component, as well the perfect spacing between it and the front section. Additional air outlets at the front wheel arches help balance the aero loads even further.

Air Flow through the Front Section

An ideal air flow over the front of the car is equally important for a balanced driving behavior at high speeds. The optimal amount of air must pass through the radiator, so it can provide sufficient cooling for the 8.0-liter W16 engine at full load. The airflow through the Chiron Super Sport’s radiator is about 8% higher than that of the Chiron in order to guarantee a perfect air balance. In addition, most of the flow passes the new air curtains at high speed. In top speed mode, the front diffusors are positioned more horizontally and guide less air into the wheel arches.

Newly Developed Wings

Nine air outlets on the front wings reminisce at the style of the iconic super sports car of the 1990s, the Bugatti EB 110. Bugatti built the EB 110 as a super sport variant between 1993 and 1995, employing principles of lightweight constructions, as well as power, luxury and exclusivity. It was the first super sports car with a carbon fiber body, all-wheel drive and four turbo chargers. The V12 turbo delivered more than 610 PS and enabled the EB 110 Super Sport to set several records, including one for its top speed of 351 km/h. The EB 110 SS featured five cylindrical air inlets to provide the proper air flow for the engine compartment. In the Chiron Super Sport, the front wheel arches also have nine cylindrical air outlets. Thanks to Computed Fluid Dynamics (CFD) simulations, experts were able to calculate the exact airflow rate to achieve a perfect aero balance. By using cylindrical air outlets, Bugatti avoids situations in which the dynamic pressure in the wheel arches of the Chiron Super Sport would lift the front of the car. So, this component creates a downforce without building further resistance, as would be the case with an additional spoiler. These air outlets generate approximately 20 to 30 kilograms of additional downforce at 380 km/h, thereby helping to balance all sources of downforce.

New Wheel Arch Ventilation Function

The nine cylindrical air outlets are 30-millimeter-deep wing penetrations, connected to the respective wheel arch by a special carbon air-guiding component, which ensures optimum air flow, while preventing stones from leaving the car. At the same time, the new wings improve brake cooling. Similar to a chimney, a vacuum caused by the airflow along the car’s body extracts air from the wheel arches. In addition, the air is guided through special venting ducts and sucked out of the wheel arches behind the front wheels. Stylistically, these elements are placed like gills behind the front wheels.

Handmade Wings

The wings weigh approximately four kilograms and are hand-crafted from clear-coated carbon, with fibers running across the edges. Each of the nine cylindrical vents is a different size. For aesthetic reasons, the visible openings are identical. In addition, the newly developed wings comply with global safety regulations regarding pedestrian and impact protection. For this purpose, the very rigid construction is weakened in certain places to absorb energy. Thereby, the wings can deform in case of slow-speed impact, while remaining extremely rigid at high speeds.

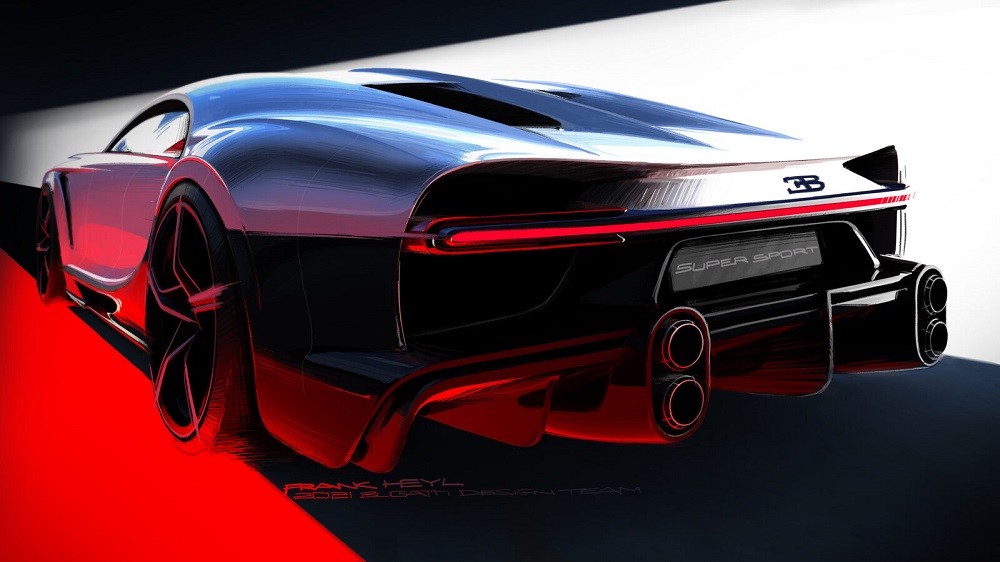

A Longtail for High Speeds

The first thing one notices when looking at the Chiron Super Sport is its tail section – referred to as a longtail – which has been extended by 25 centimeters. At high speeds, it ensures that the air flowing along the top and bottom of the vehicle creates a break-away area that is as small as possible. To achieve a balance between down forces and lifting forces, Bugatti precisely aligned the performance of the rear wing and the diffusor, by enlarging the diffusor’s profile. This moves the break-away edge upward, so that the break-away area of the tail section is minimized. This significantly reduces the losses generated in this area, leading to much lower wind resistance – which is what slows the car down.

Larger Rear Wing

In handling mode, the blade of the rear wing, which has been extended by 23 millimeters and thereby gained 8 percent in size, makes the airbrake far more efficient, in combination with the larger diffusor. In top-speed mode, however, the rear wing is retracted almost completely, allowing the car to make full use of its longtail design concept. In this way, the laminar flow can establish itself across the entire length of the car’s body, until it breaks away at a defined location of the tail section. This reduces air resistance significantly.

“In top-speed mode, the Chiron Super Sport generates only minimal resistance, making it perfectly balanced and as aerodynamically efficient as possible,” says Frank Heyl. The goal was to perfectly balance downforce and lift at speeds above 400 km/h. “The Super Sport generates just enough downforce to stay stable above 400 km/h. That’s essential at this speed to avoid putting excessive pressure on the tires,” Frank Heyl continues. At these speeds, lift is enormous, meaning the Chiron Super Sport has to neutralize it by creating considerable downforce.

Larger Diffusor

To create as little resistance as possible and stabilize the car at speeds above 400 km/h, Bugatti also had to redesign the diffusor on the underside of the Chiron Super Sport. Due to the elongated tail section, the diffusor gains about 23 millimeters in length. To increase the diffusor’s effectiveness and give it more space, Bugatti moved the exhaust section from the center to the sides. The two tailpipes are positioned one above the other to reduce the effective area of the diffusor as much as possible. This increases the total size of the diffusor by 32 percent, compared to the Chiron3. “In addition, the most efficient area, the center, is freed up for uninhibited airflow and the optimum effect,” says Christoph Dobriloff, Aerodynamics Development Engineer at Bugatti.

Exhaust System made with a Titanium 3D Printing Process

The two exhaust bezels are a special feature. Titanium 3D printing was employed to create an extremely thin double-wall structure, some of it as thin as 0.4 millimeters, pushing the envelope of what is technically feasible. A lattice structure gives the component stability, and also provides space for airflow channels.

The double-wall structure insulates the titanium bezel, while the airflow reduces its temperature. To protect the surrounding carbon parts from excessive heat, the Chiron Super Sport has additional air inlets in its undercarriage. Cold air circles around the exhaust components and exits through the tail pipe bezels. This way, the exhaust gas flow, which can reach temperatures of up to 850 degrees Celsius, is surrounded by a sheath of cold air. It prevents hot exhaust fumes from impinging on the car’s tail section.

“Even at full power and top speed, exhaust gas does not influence any other components and is prevented from flowing back,” says Jens Wenge, Construction Engineer at Bugatti. Titanium itself reaches its melting point only at 1,668 degrees Celsius. Other advantages of titanium printing include precise edges and small gaps, leading to improved airflow properties and minimal rework. After the 3D-printing process is finished, a bezel is simply blasted and cleaned with compressed air. If desired, it can be painted black. In addition, a 3D-printed titanium component weighs only 930 grams, which is 570 grams or one-third lighter than a precision casting component.

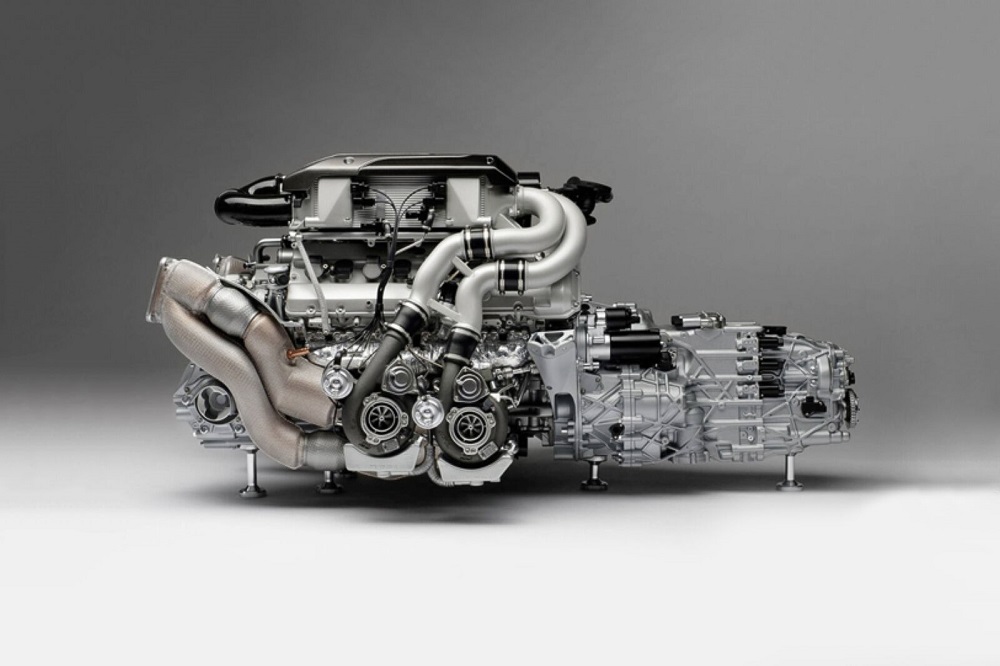

W16-Engine with more Power and higher RPMs

In order to reach the top speed of 440 km/h, Bugatti stepped up the maximum power of the 8.0-liter W16-engine to 1,600 PS – an increase of 100 PS. For more agility, the engine delivers an additional 300 rpm and a higher power plateau at 7,100 rpm, up from 7,050 rpm. 1,600 newton meters of torque are available from 2,250 to 7,000 rpm, compared to 6,000 rpm before. To achieve this increase in power, engineers redesigned many components. Pistons have been reinforced. Thanks to a stiffer pressure control spring, the oil pump now supplies more lubricant at a higher pressure to engine parts like the crankshaft, valves, chain drive, camshaft adjustment and piston cooling. At full load and nominal rpms, more than 140 liters of oil flow through the pump every minute.

Higher performance and rpms have led to an increase in vibration which, in turn, creates more stress on the chain drive and the valve train, including the four camshafts and 64 valves. To improve durability at maximum rpms, Bugatti resized the bearing bolt of the chain tensioner, among other components. This also required a modification of the cylinder head. Modified valve springs with steel spring bases are now able to withstand the increased stress. In order to comply with current legal acoustic requirements, new, multi-layer, fiber-reinforced chain cases are used to reduce noise emissions. A modified torsional vibration damper at the crankshaft, which is mounted on the belt drive side, allows the engine to run much more smoothly. In addition, Bugatti adjusted the auxiliary component drive, including generator, air-conditioning compressor, water pump and tandem pump to compensate for higher rpms.

More Efficient Turbochargers

Apart from higher rpms, the increase in performance is also a product of optimized and newly developed turbochargers. All four turbos now use a compressor wheel that grew in size from 74 to 77 millimeters, to allow for a higher throughput. The turbine wheel grew from 64.4 to 67.2 millimeters in diameter, to be able to provide more compressor power, necessary for the increase in boost pressure. At full load, 4.8 tons of air flow through the four turbochargers every hour. Optimizing blade geometry improves thermodynamic efficiency. The throttle response is similar to that of the Chiron.

“Despite the increase in performance, the weight of the engine is unaffected, and the response of the turbochargers remains at the same positive level provided by the 1,500 PS engine,” says Andreas Kurowski, Engine Development Engineer at Bugatti.

New Gear Ratio

To achieve the top speed of 440 km/h, the 7-speed double clutch gearbox employs a new gear ratio. The seventh gear is 3.6 percent longer, compared to the Chiron. Due to the increased performance, at full load and full acceleration, the 7-speed double clutch gearbox shifts from sixth to seventh gear at 403 km/h. The Chiron Super Sport accelerates from 0 to 200 km/h in 5.8 seconds and reaches 300 km/h in 12.1 seconds. The difference is even greater for the acceleration from 0 to 400 km/h, a speed which the Chiron Super Sport achieves in 28.6 seconds. This makes it 12 percent, or four seconds, faster than a Chiron. To make traction interruptions during shifting imperceptible to driver and passengers, the boost pressure control has been refined for the individual gears. Even at 6,000 rpms, the acceleration continues relentlessly and gives the Chiron Super Sport an enormous push up to 7,100 rpm.

Newly Developed and Refined Chassis

Bugatti redeveloped the chassis of the Chiron Super Sport with utter focus on high-speed performance and the car’s new aerodynamics. For this reason, engineers increased the rear axle spring rate by seven percent, compared to the Chiron, in order to further stabilize the Chiron Super Sport at speeds above 420 km/h.

“The longtail design leads to a shift in axle load distribution, which we have taken into account when we tuned the chassis,” says Jachin Schwalbe, Head of Vehicle Development at Bugatti.

In combination with the longer tail section and the modified front, the Chiron Super Sport achieves an improved aero balance at high speeds. For this purpose, the engineers retuned the electronically controlled chassis and adjusted the damping of vehicle movement. Within six milliseconds, almost in real time, it adjusts the dampers and adapts to the vehicle’s movements.

New Michelin Tires for Top Speed

Newly developed Pilot-Sport-Cup-2 tires from Michelin, optimized for the higher top speed, offer more rigidity and running smoothness above 420 km/h than the Chiron. The individual tires were tested at speeds above 500 km/h. This has been made possible by a new technology using reinforced layers, capable of withstanding incredible forces – tested in a facility originally built for fighter jets. The front tires are sized 285/30 R20 ZR and the rear tires 355/25 R21 ZR. After production, every tire is x-rayed to detect even the smallest irregularities. Michelin Pilot-Sport-Cup-2 tires are designed for extreme longitudinal dynamics and therefore support the philosophy of the Bugatti Chiron Super Sport.

Lightweight Rims with a New Design

To reduce unsprung mass, Bugatti developed new five-spoke aluminum rims, weighing four kilograms less per set than those of the Chiron. They also increase rigidity for longitudinal dynamics, making them a perfect fit for the Chiron Super Sport. As an option, Bugatti offers a magnesium rim set that weighs 16 kilograms less than regular Chiron rims, thereby further reducing unsprung mass at the axles.

With the Chiron Super Sport, Bugatti developed an extreme hyper sports car. Many technical modifications and the pursuit of perfection make it the fastest production vehicle with a very own character, a unique design and an unrivaled level of luxurious comfort. Bugatti manufactures the Chiron Super Sport at its headquarters in Molsheim. The first vehicles will be delivered to their new owners in early 2022, at a net price of 3.2 million euros.

If you are interested in more news click here.