The US car manufacturer Czinger Vehicles presented its new hypercar 21 C in Frankfurt – it could be seen there in a new body variant.

The Czinger 21C is an unusual car

1250 hp hybrid drive and a driver’s cabin like a fighter plane. There are to be around 80 vehicles of it once, the price: just under two million dollars. “Oh, go ahead and touch it,” says Kevin Czinger. The U.S. American is standing in Frankfurt’s Klassikstadt, where the hypercar named after him was presented mid of last year. Czinger is visibly proud of the car, which is sold in Germany by the Frankfurt-based Dörr Group. Not just because it’s fast – he’s also concerned about something else. In an interview, the entrepreneur talks about e-cars, 3D printing and how he wants to democratize production.

Mr. Czinger, what an entrance! It makes me wonder: Are you not just a smart superhero, but a green superhero?

Mr. Czinger, what an entrance! It makes me wonder: Are you not just a smart superhero, but a green superhero?

You know, in 2006 I founded the e-car maker Coda and a battery company. Even then, it was clear to me how important EV battery technology is if we want to stop destroying the planet. But one thing I learned quickly – and perhaps too late – is that battery manufacturing can also have an incredible effect on the environment. Nearly 80 percent of batteries for e-cars are produced in China – in factories that run on energy from coal. This emits around 200 kilograms of CO2 per kilowatt hour of battery capacity. So the realization is: manufacturing is super important. And then I asked myself: what do we need to do?

And what was the answer?

Well, this is all an exciting journey for us as we push the boundaries of design and performance. The resulting answer was: we need to change the production process. And we need to do it in a way that reflects nature.

That’s where 3D printing comes in, I suppose?

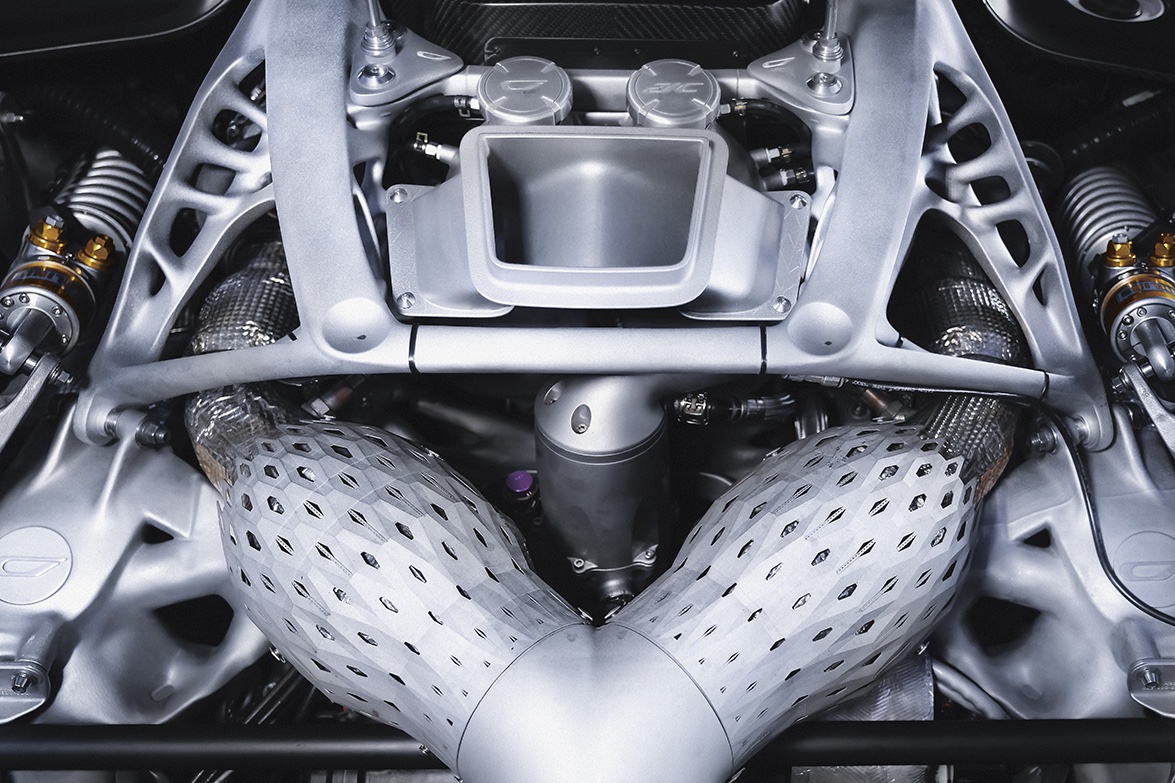

We’ve created the most technologically advanced hypercar in the world. From the AI-driven design software used to develop it to the patented alloys used to print its structures, the 21C embodies more than seven years of development and hundreds of millions of capital investment. In that respect, 3D printing was only one aspect, albeit an important one, in the whole system. It would be a mistake to think of a particular technology when looking for solutions, because then you’re also thinking about the limitations that an existing technology has. Instead, you have to start with a blank sheet of paper. The question must be: How is a digital production platform built? And not: What can I do with a 3D printer? That only leads to dead ends. But you asked why it had to be such a radical supercar of all things …

We’ve created the most technologically advanced hypercar in the world. From the AI-driven design software used to develop it to the patented alloys used to print its structures, the 21C embodies more than seven years of development and hundreds of millions of capital investment. In that respect, 3D printing was only one aspect, albeit an important one, in the whole system. It would be a mistake to think of a particular technology when looking for solutions, because then you’re also thinking about the limitations that an existing technology has. Instead, you have to start with a blank sheet of paper. The question must be: How is a digital production platform built? And not: What can I do with a 3D printer? That only leads to dead ends. But you asked why it had to be such a radical supercar of all things …

That’s right, the answer is missing so far.

Well, if you want to commercialize something, you look for the smallest viable version with the lowest number of units – and the most eye-catching design! For the digital manufacturing system we developed, it just became this hypercar.

So this car is also a wake-up call to the industry: “Hey guys, our system works and can be extended to other, simpler cars in the future“?

Over the past five years, we’ve already worked with major car companies, including German ones. In September, a production program with a much higher volume will start. With the Czinger 21C, I really wanted to show two things: the cutting edge of technology and the business model that the car represents.

What is special about the business model?

The companies that will produce cars or other things in the future will no longer need large production facilities. Take the hypercar: Czinger Vehicles simply sends the 21C data to Divergent 3D’s factory, where those structures are then printed and assembled. So Czinger Vehicles is basically a design company that doesn’t need much capital. Imagine: Designers have access to the means of production without being shackled to capital.

What would be the consequences of that?

It would unleash human creativity. Whether in Renningen, Swabia, or Houston, Texas, small teams could use software to create perfectly optimized structures that would then be 3D printed in a local Divergent factory. I am certain that we are currently experiencing the transformation from analog production to digital. Another industry has already undergone this change: if you wanted to build a web-based business in the 1990s, you needed real infrastructure like servers. Today, it all happens via the cloud. And it can go the same way for manufacturing. So the long-term vision for Divergent 3D is to set up small factories all over the world where products can then be manufactured.

It would unleash human creativity. Whether in Renningen, Swabia, or Houston, Texas, small teams could use software to create perfectly optimized structures that would then be 3D printed in a local Divergent factory. I am certain that we are currently experiencing the transformation from analog production to digital. Another industry has already undergone this change: if you wanted to build a web-based business in the 1990s, you needed real infrastructure like servers. Today, it all happens via the cloud. And it can go the same way for manufacturing. So the long-term vision for Divergent 3D is to set up small factories all over the world where products can then be manufactured.

And that won’t just be hypercars anymore.

Exactly. And that’s why it’s not me, it’s the car that’s the green superhero. We want to change the structures, how developments take place, how people think about design and production – and that’s not a project for one year, it’s for 20 years.

Rainer Dörr, founder and owner of the Dörr Group and dealer of Czinger, adds: “Czinger is a revolution that will be sustainable. And Dörr Group’s customers have a strong racing affinity, are always on the lookout for new technologies, and are therefore open to precisely such products.”

This article had been previously published in RETROWELT No. 24/2022

Photos by Automotive COLOGNE

![Is this the greatest racing film oat?

In “Ford v Ferrari”, one of the most important

moments comes when Ken Miles takes the GT40 out for a test run after it’s fitted with its massive new 7.0 litre V8. The scene captures a turning point in Ford’s effort to challenge Ferrari at Le Mans, with Miles pushing the prototype hard at Ford’s Dearborn test facility.

With his trademark intensity, Miles immediately feels how the car responds to the raw force of the 427 cubic inch engine. The sound, speed, and feedback through the steering wheel signal that the GT40 is finally becoming something special.

The moment isn’t just cinematic drama, it reflects real history. The big block 427 gave Ford the power it needed to fight Ferrari, and Miles’s deep mechanical understanding played a key role in shaping the car’s behavior on track.

Despite Ford pouring more than $25 million into the program, it was experiences like this, Miles sensing every detail from behind the wheel, that turned early prototypes into Le Mans winning legends.

( Media via “Ford v Ferrari” [2019] )](https://collectorscarworld.com/wp-content/plugins/instagram-feed/img/placeholder.png)