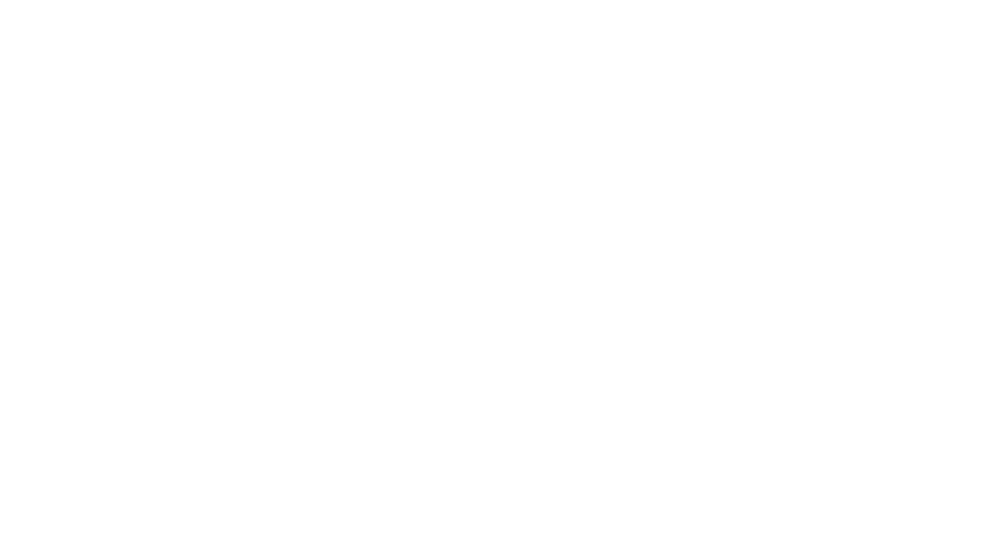

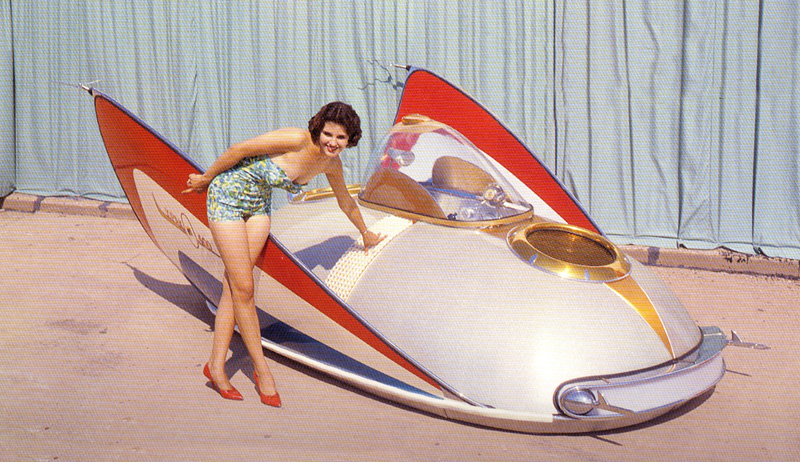

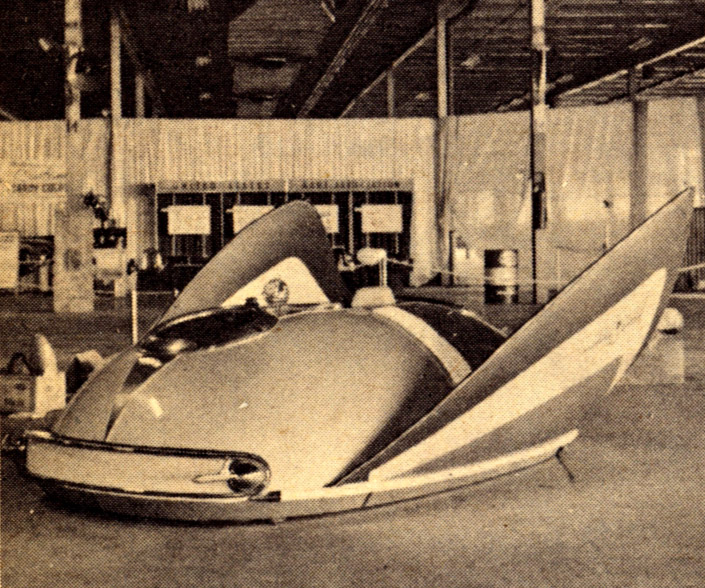

The XPAK 400, translated from Martian, means air car. It was built and designed by Barris Kustoms of North Hollywood, California. It had no wheels, transmission or rear end, and as a matter of fact, it featured no frictional moving parts at all. The car rode on a five inch cushion of air and it was drivable on both land and water. The air was drawn in through the front and rear openings into the open plenum chamber with outlets through a combination of peripheral jet inserts.

Power came from two jet aircraft starter motors 24 volt D.C., four horse power that turned 40,000 RPM at 300 AMPS. This was reduced 8 to 1 to absorb the amount of load combination of horsepower. Balanced 20 inch cast aluminum fans pushed 11,800 C.I.M. free flow and under 7/8 inch static water pressure had 7,600 C.I.M. Dry weight of the car was 422 pounds including all the accessories. Movement was obtained by a revolving jet nozzle which had an air thrust into the right, left, forward, reverse and stop.

The top was vacuum formed by Plastic Dynamicsover a male mold using 100,000 Butyrate tinted plastic. The scoop on the top housed a Penta Prism rear view mirror which could be seen from the inside of the cab. The headlight was a curved reflective fluorescent triple tubes which threw out a clear even light over 100 feet in the front and had no glare on the approaching vehicles. Fry’s Plastic of Los Angeles had an 1/8 inch red translucent plastic with a refective backing insert in the complete rear fin taillight assembly. Twelve mill ruby red neon heated blown to fit the contour in each fin section lighted up the complete area. Frosted white plastic was fitted into the front headlight for protection with a hand formed chrome rim and grille combination. White circular suction cups were installed on the sides of the body for step plates. The frame construction was made out of 3/4 inch alloy round tubing. It was 12 inch long, 6 inch wide, and 30 inch high. Jack Sutton hand formed all the body panels from 040 half hard aluminum. Gold checkered plastic covers were used over the openings of the large tunnels to the blower for protection from the blades. Air stream indicators were mounted into the grille to register the amount of speed while going through the air since there were no wheels or rear end. Four inch polyethylene circular skirt were installed on the lower portion of the body.

Contoured curved body formed unbreakable fiberglass bucket seat were installed in the cockpit with a waist high safety belt. Air foam was used to fill the inside white pearl naugahyde covered seat and white plush rugs. There was an impact adjustable air foam head rest on a gold coil spring. The phono-vision dial telephone with a vision screen enabled you to see who you were talking to when dialed in with the double transister T.V. camera and microphone. A six inch television screen was mounted into the dash and was operated on any wave length from a transformer. A radar screen was also mounted on the dash, and it sent waves to pick up size of obstruction on the highway. Complete car was operated by sound waves and it would demonstrate the controls by a small push button box unit 50 feet away from the car. Start, stop, right, left, on/off, of the neon fluorescent lighting system and raise and lower the top were all done by wireless remote control. All electronics were on circuit breakers, racheted relays and solenoids. All the electronics were on circuit breakers, racheted relays and solenoids was engineered by Earl Wilson.[2]

In 1959 Barris Kustoms debuted their futuristic air car, the XPAK 400 at the New York World’s Fair. The XPAK 400 featured 35 coats of nitro cellulose lacquer, that according to a press release by Barris Kustoms, contained a million particles of chromed aluminum called “Metalflake”. The press release could further state, that Metalflake was a revolutionary new development by the Dobeckmun Company, a Division of the Dow Chemical Company. The particles were precision cut, coated aluminum foil that gave a metallic finish, and it was supposedly the first time the product was available for commercial use. A trial was offered to George Barris for the XPAK 400 since it was going to be displayed at the National Car Show in Detroit. George used plain silver flake for the body. The overall reflection quality of the flake was softened by the addition of a small amount of pearl. “George’s early experience with the flake proved that it would be a wild wild finish, subtle and velvet soft in the indirect lighting, yet extremely lively where the strong light is directed”. The fins featured 30 coats of imported Swedish pearl of essence which was made of crushed fish scales and crushed diamond dust. It was also painted in Kandy translucent red, white and blue.

The car was designed and built to be demonstrated for the public showing how an air vehicle operates and it was mounted on a guide rail for safety. All exterior trim was gold plated for added attraction. All engineering and styling on this car has been used for today’s vehicles.

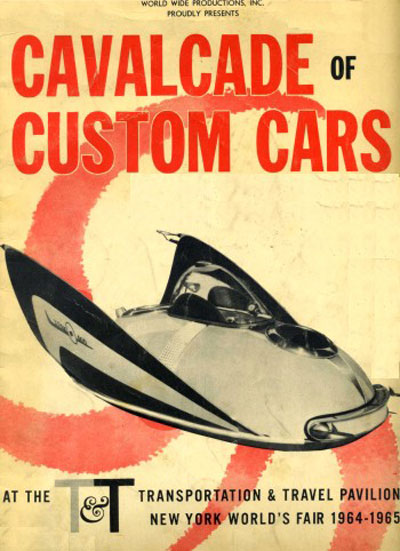

In 1964 the XPAK 400 was shown at the Cavalcade of Custom Cars exhibit that was held at the Transportation & Travel Pavilion at New York World’s Fair. According to the souvenir program from the show, the air car had caused more talk in the transportation industry than anything since the development of the jet engine.

Report by kustomrama.com