On February 7, 1968 US Air Force Major Robert W. Border of the 57th Fighter Interceptor Squadron in Keflavik, Iceland sent a letter to “Automobile (sic) Ferruccio Lamborghini, Bologna, Italia” . The letter started: “ I am desirous of purchasing direct from you (the factory) a 1968 Lamborghini Miura P400, for delivery in June or July 1968, under the privileges allowed personnel of the diplomatic corps”. He went on to explain that he served as a liason between the Iceland Defense Force, the American Embassy, and the Iceland Civil Aeronautics Administration. Therefore “he sincerely hoped” that he would qualify for the privilege of a diplomatic discount on his dream car.

One may wonder what exactly the Iceland Defense Force looked like, but the Lamborghini factory harbored no such doubts and responded on February 16, 1968: “Considering your position and bearing in mind that you are living in Iceland, we are pleased to offer this car at the special price of Lit 7,000,000.- (=$11,200) net instead of Lit 7,700,000.-“. They asked the Major of the famous “Black Knights of Keflavik” squadron to keep this arrangement confidential and agreed to the delivery window of June/July 1968.

And thus started the story of Lamborghini Miura P400, chassis #3706.

Unfortunately, 1968 was a year of considerable industrial and social unrest in Italy and even the Lamborghini factory could not evade the troubles that almost brought the whole country to a standstill. In 2014, Ingrid Pussich, the famous assistant to Ferruccio Lamborghini remembered those days: “. Those were also the years of political protests, of workers, for whom the only possible color was red and who therefore were not grateful to him that he had created jobs for so many people. I remember that time when, in the hot autumn, the workers invaded the atrium that led up to the offices and when he appeared leaning on the railing and trying to calm them down, they started insulting him and after a while he said: “Guys, fe ‘ mo qual c’a vli” (boys, do what you want), in the meantime I’m going to the beach in Milano Marittima” and it was really good.”

Major Border, who planned on picking up the car in person at the factory, sent repeated notes and telegrams asking for a firm delivery date. In mid-June 1968, the factory asked Major Border in a telegram, whether he would be prepared to accept a green Miura with black interior which they would be able to deliver by July 10, 1968 (most likely as a result of a customer cancelling their order). The Major responded: ”I still desire the color of red, as illustrated in August 1967 Playboy Magazine” and asked that the car be treated with “undercoating”. To which the factory in its next communication responded with a confirmation of a September 10, 1968 delivery date for a red Miura at the factory and the priceless statement: “We seize the opportunity of asking you to kindly explain us, what do you mean by “undercoated”, as we are at a loss to understand it.” After an explanation by Major Border, the factory used the August 1, 1968 presentation of a pro forma invoice to assure the Major “that all our cars are properly protected by special substances, so that no additional protection is required”.

Factory records show that assembly of Major Border’s Iceland Miura P400 was started on July 24, 1968 and finished on September 3, 1968. It was given chassis number #3706, had engine #2293 installed, and was finally delivered on September 10, 1968.

Fast forward and the Iceland Miura was acquired by its current German owner in the United States and brought back to Germany for restoration. After a a hard life ending in engine failure, the car had spent its last 23 years in a race shop in Madison, WI, awaiting a restoration that never happened. When it was finally sold to Germany, all of the “special substances” applied by the factory had failed, the body was rusty, and the engine and many other cmponents were in boxes.

The body was expertly restored by Patrick Dutschmann of Body Concept in Kornwestheim, who has built a well-deserved reputation for the restoration of high-end Italian coach-built cars ( Lamborghini, ISO, Maserati, etc.). Special attention was paid to strengthening the rear lower frame rails and the triangular bolt-on engine mounting bracket which are often bent or cracked. Both the front and rear hoods were disassembled, separating the steel frames from the aluminum skins. Afterwards, great attention was paid to re-creating the correct, original color of “Rosso Miura”, using a rare and original Bertone/Lamborghini color fan, and the original vinyl interior with correct Bertone perforations.

Unfortunately, much of the assembly, suspension and engine work, entrusted to a Lamborghini expert, who shall remain unnamed, was not to the high standards of the body and interior work. Finally, the owner moved the half-assembled project to TG Classics of Willich, Germany, with whom he had already done several restorations, one of which, in 2016, had even scored a class win at the prestigeous Pebble Beach Concours d’Elegance.

Thomas Gralak, the 35-year-old owner of TG Classics, and his team completely overhauled the engine (for the 2nd time) and corrected any number of assembly mistakes and quality issues. The engine was completely disassembled and cleaned. All cast aluminum parts were vacuum sealed to prevent leaks from oil seeping through the original, somewhat porous cast material. Insufficiently repaired block damage was corrected using laser welding. New cylinder liners were installed and the original 10mm head bolts were replaced with 11mm ones, a reinforcement the factory did on later cars. New Italian custom pistons were installed and valves and valve guides were replaced using modern valve seals. Camshafts were reground and heat treated and the camshaft chains were replaced. The rotating assembly was balanced and the cylinder heads were resurfaced. Custom head gaskets with silicone sealing were sourced from a specialist supplier in Australia.

The traditionally weak water / oil pump seal was replaced with a modern ceramic design and the corroded pump shaft remanufactured. All induction tubes were resurfaced to create an absolutely level base for the famous triple Weber 40 IDL 3C carburetors. The carburetors had to be re-restored, with every lead plug removed to expel residual media from a prior ill-advised media blasting treatment. A special chemical process was used to obtain the original brownish-greenish finish of the carburetor bodies.

Oil circuits for the engine and the gearbox had already been separated, but TG Classics developed a more elegant oiler design for the oil-starved transfer gears, utilizing custom oil nozzles. The gearbox received all bearing upgrades that were incorporated in the final Miura SV cars as well as new synchro rings from Italy.

The ignition system was converted to an electronic system. The cooling system was upgraded with a re-cored radiator and continously variable, electronically-controlled SPAL fans which were modified so as to maintain the original look, including the hammerite 6W Lucas motor housings.

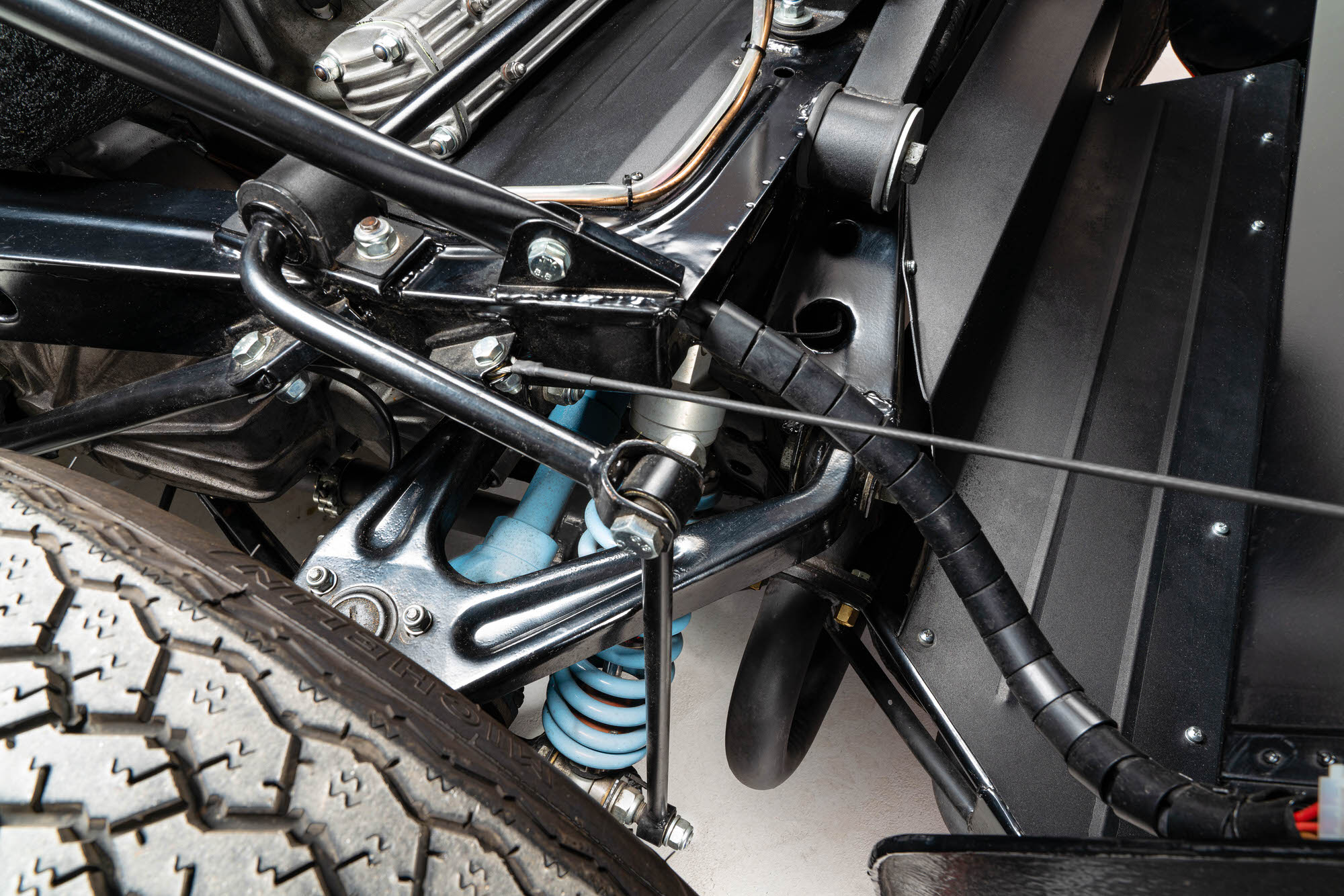

The owner of the Iceland Miura likes to drive the car under regular traffic conditions and is sensitive to functionality and safety. The original 2nd generation Bertone door strap mechanisms (different from the earliest Miuras), which never last very long, were replaced with a modern mechanisms which did not require any modifiction to the doors and are indistinguishable for the untrained eye. Discreet, automatically retracting 3-point seat belts with classic lift latch buckle (matt black of course) add a modicum of safety. The Girling brakes were redone by a a specialist brake shop in the Netherlands, new discs had been installed earlier. To improve the car’s stance and looks, a custom, adjustable Wilbers suspension setup was sourced and Miura SV-style 9×15 inch magnesium rims were installed on the rear wheels, all modifications which can be easily reversed. Michelin XWX 225/70-15 tires are used in the rear and 215/70-15 in the front.

After almost 30 years off the road, the Iceland Miura is back on the road and used in the way its creators intended. Technically, it is a better car than it was when it left the factory. 55 years after the car’s production, it requires detailed knowledge, meticulous research, access to the best sources, tradtional craftsmanship of the highest order and a joyful passion to restore such a magnificent machine. Major Border would have loved it…

Report by Jürgen M. Wilms

Photo Credit: ABBILD Filmproduktion /Christian Henschel