75 years ago, from June 5, 1945, the British military entered its zone of occupation, replacing the US troops. In Wolfsburg, the British Military Government assumed trusteeship over Volkswagenwerk GmbH, beginning a unique post-war story. The key figure in this story is 28-year-old Major Ivan Hirst. With a talent for improvisation, organizational capabilities and tremendous farsightedness, he reshaped the armaments plant, which had been largely destroyed and was intended for demolition, into a civilian car factory. This way, the British prepared the ground for the later global success of the Beetle and laid the foundation for today’s Volkswagen Group. Volkswagen honors the British era with the documentary film “My brief was very simple“, in which Ivan Hirst tells his Volkswagen story.

Documentary film “My brief was very simple“

Volkswagen Heritage has taken the occasion of the 75th anniversary of the assumption of British trusteeship to publish the 30-minute documentary film “My brief was very simple” on YouTube for educational, research and media work. Five episodes document the decisive ground-breaking phase of Volkswagen after the Second World War. In one of his last interviews, in 1999, Ivan Hirst tells the story of the British trusteeship over the company in Wolfsburg precisely 50 years after responsibility for Volkswagenwerk GmbH was returned to Germany.

“Initially,” Ivan Hirst begins his Volkswagen story, “my brief was very simple. Go to Wolfsburg, find the factory and sit on it. They didn’t even say it was a Volkswagen factory.” Major Hirst arrived in Wolfsburg in August 1945 and was satisfied when he took his leave four years later in August 1949: “There was a modern factory, ready to go, with a labor force, a German management and a product that was proven,” Hirst remembers. “And when the currency changed in 1948, it took off: Volkswagen went round the world.”

The era of the British: Volkswagen in 1945 to 1949

Occupation and assumption of trusteeship

At the end of the Second World War, Volkswagenwerk GmbH had lost its proprietor, as the National Socialist organization Deutsche Arbeitsfront (German Labor Front) had ceased to exist. The plant, which had been planned by the National Socialists as an exemplary factory for the production of the KdF-Wagen, produced military goods during the Second World War with about 20,000 forced laborers. As a former armaments plant, it was scheduled for demolition after the war. However, following the liberation of the plant, the Americans had established a workshop there. When the British entered their zone of occupation in June 1945, they took over the trusteeship of Volkswagenwerk GmbH and assigned 28-year-old Major Ivan Hirst to Wolfsburg. He assumed responsibility as Senior Resident Officer and rapidly saw that the factory offered much greater potential than for the use of the factory halls as a repair shop. Many of the machines and tools intended for civilian production had been stored at other locations during the war and were returned. The damage to the factory halls was considerable, but repairable, and civilian production of the Volkswagen saloon appeared to be possible. The German economy was devastated. The situation was dominated by poverty and shortages. The roads and railways had been destroyed and there were no means of transport. Hirst recognized that economical vehicle production would help in remedying the transport bottlenecks of the British Army. Over the course of time, it was found that the solution was in line with British policy for Germany, which saw material security and a future perspective for the German population as key elements in the development of democratic structures.

A major contract and a reprieve

Colonel Michael McEvoy, Ivan Hirst’s superior, supported the resumption of civilian production at Wolfsburg. McEvoy had already seen the Volkswagen saloon in 1939 at the Berlin International Motor Show. In order to convince the British Military Government, he presented a vehicle at headquarters that Hirst had found at the factory site, and had painted in a khaki color. On August 22, 1945, the British Military Government issued an order to supply 20,000 vehicles for the British military administration. Two weeks later, a second order followed for another 20,000 vehicles. This meant that the dismantling of the factory had been postponed by four years. The first civilian vehicle already left the factory on December 27, 1945. However, the future of the factory remained uncertain and the route to stable production was connected with challenges.

Reconstruction and a new start

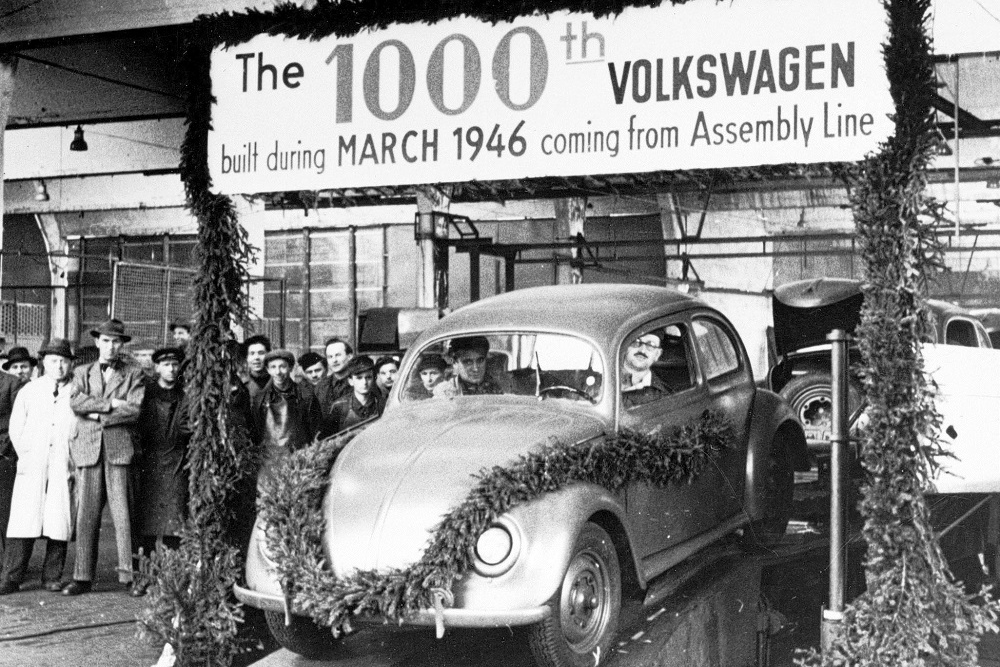

Initially, the factory had to be rebuilt, a process that also continued after production had started. Parts and raw materials such as steel, batteries, textiles and glass were in extremely short supply in post-war Germany. Through skilful negotiations, Hirst was able to persuade the British Military Government to allocate the materials required. Materials were scarce but they were sufficient to produce the monthly target of 1,000 vehicles, which was reached for the first time in March 1946. The Volkswagen plant only had a small workforce and the recruitment of additional workers was a further challenge. Hirst was pragmatic and also offered German prisoners of war a job. During the first few years, it was difficult to obtain supplies for the workforce. Hirst improvised and was able to organize food and other items through his contacts. In October 1945, the first freely elected Works Council was formed – which the British saw as a key step towards democratization. At that time, the main task of the employee representative body was to ensure that shortages were fairly and equitably distributed.

Future-oriented structures

The denazification process conducted by the allies led to the dismissal of the previous plant manager, who was succeeded by Dr. Herrmann Münch, a lawyer, in June 1946. As managing director, he forged ahead with production with the support of a commercial and a technical director. Following these organizational changes, the British improved the quality of the vehicles and the production processes, trained customer service personnel and started to develop a dealership organization. These efforts were so successful that Volkswagen was able to start exports in October 1947. In 1948, the factory already produced 19,000 vehicles, of which about a quarter were intended for export. At the same time, the production of spare parts for the steadily growing service network started. In view of the good prospects for the future, the British trustees decided to transfer the management of the plant to an expert and to return the company to German responsibility. Heinrich Nordhoff was appointed managing director with effect from January 1, 1948. Three years after the end of the war, Volkswagen had developed from a ruined armaments plant into a well-functioning car factory with 8,700 employees. While the living and working conditions in Wolfsburg where perceptibly improving, the situation in Germany as a whole was still dominated by shortages. The decisive turning point came on June 22, 1948 with the currency reform, which initiated an economic boom in the three Western zones of occupation and gave Volkswagen the decisive impetus. For Ivan Hirst, everything was moving in the right direction. On October 8, 1949, the British Military Government transferred the trusteeship of Volkswagenwerk GmbH to the German government.

Report by volkswagen-newsroom.com